Beyond Leather

How Modern Meadow is creating lab-grown leather to clothe the world, sustainably.

How Modern Meadow is creating lab-grown leather to clothe the world, sustainably.

It’s a wild chase: a woolly mammoth to the left, a rival tribe to the right. The world is reduced to streaks of greens and browns as you run, faster than you possibly thought you could. The atmosphere is tense. You fly by, stones cutting into your bare feet, lungs expanding to their maximum to get air in, and the few animal rags you wore left to the mercies of the muddy ground. This is a race that will end in blood, bones, and —

Failure?

But when you have shed every little bit of your attire (and reputation), there’s only one defendant standing out for you: your skin.

We rarely think about skin, except in relation to the clothes that cover it. But if you think about it, our skin is really extraordinary.

To start with, skin is waterproof and extremely washable. No matter how messy or dirty it gets, chances are you can quickly wash it off — and without having to go through a whole “soak, wash, rinse” cycle. The marks that do stick on for longer get shed when our skin replenishes itself every 27 days or so. That’s right: if you didn’t wear clothes, you’d get a brand-new outfit every month. And there’s no worries about skin not fitting: it grows to take the shape of your body, and stretches or contracts as needed, as you move.

Skin is also very protective: in fact it’s your body’s first line of defence against the outside world. It does a good job keeping uninvited microbes at bay and controlling your temperature.

And if that’s not enough, guess what the body’s largest sense organ is? That’s right: skin. While eyes perceive the world from the middle of our faces, and ears from the side of our heads, it’s skin that’s always probing, and always aware of action, all over your body.

Skin is so awesomely designed, I’m sure that, if some alien species were to farm humans for something, it would be for our skin.

Meet Roana. She’s the cow in the picture below:

Roana’s life started out as an ordinary cow, but her friends and family are captive to humans, who rear cattle in cages for their milk and meat.

Unfortunately, cows need a lot of grass and release a lot of carbon and methane — so much so that cattle rearing is responsible for a whopping 65% of livestock emissions, and also nearly a tenth of all greenhouse gas emissions in the world. Yikes! Meanwhile, the amount of farmland that goes into growing cow food would be better used providing food for humans directly — especially in an age of impending food shortage where the United Nations are urging people to try insects.

While this number includes rearing cattle for other reasons as well, one can’t say leather is simply a “byproduct” of the industry. It is clearly a part of the business model and is an important aspect of the industry — so less leather is a big step towards less greenhouse gas emissions.

The other problem with leather is one that Roana feels more deeply, and immediately. She sees her friends and family kept in tiny, barely liveable cages and subject to all sorts of cruel acts. She’s going to see them live only a fraction of their lifespan. She’s going to see them get prematurely separated from their moms. And after that long, traumatic process, what happens to the cow hide? Sometimes, up to half of it can be wasted and just thrown away due to imperfections such as bites.

Yet, despite all these problems, the human race continues to buy and consume leather. Now isn’t that weird?

The human body louse, which lives in clothing, first diverged from the head louse about 107,000 years ago. It was probably a bit before this that humans started wearing sewn clothing—an environment tempting enough for the head louse to think of expanding its territory. Before that, humans used simple draped coverings made of naturally occurring materials like grass, shells, and, of course, animal skin.

The reasons behind covering our skin are actually pretty sensible. We humans have relatively leaner bodies, which means we need a way to keep warm. Between the two options — wait around till we evolve warmer skins, or borrow skins from animals that have already evolved them — the answer is pretty obvious. Other reasons for covering up ourselves include to protect ourselves from rashes, splinters, and insect bites, and generally protect our bodies from the harsher parts of the environment.

The first garments were simply draped on, but over time humans figured out how to sew leather into specific shapes. And then came the real revolution: woven fabrics, which were lighter, easier to grow, and more comfortable because they could stretch to fit the shape of your body. The agricultural revolution was an added bonus, because it was that much easier to get material for fabric: we were growing the plants anyway.

So, why are we still growing animals?

That is, incidentally, the question that Andras Forgacs and his father Gabor Forgacs asked themselves. So they joined up with a few other people and started a company, Modern Meadow, that aims to grow not animals, and not plants, but…clothes themselves.

To grow your own leather, there are quite a few special ingredients you need, but here’s the most surprising one: yeast.

When I mention yeast, what immediately springs to mind is bread. But if you dig in a bit, you realise yeast is actually involved in various kinds of fermentation. Drinks like beer, wine, and sake are fermented with yeast. The traditional idli of south India includes a combination of bacteria and yeast, as does natto, the fermented soybeans of Japan. Of course, all these foods use different kinds of yeast to grow — as does lab grown leather.

So what is yeast, exactly?

Unlike other Snipette pieces, this one involves quite a bit of technical terms and explanations. If you want to skip those, feel free to use the "math-free" toggle below:

You can also toggle each individual section: just look out for the emoji on the left margin!

Imagine yourself as a single-celled fungus floating through the air. Suddenly, you alight on a vast, edible landscape: moist, sugary wheat! Excited, you dive in and begin to eat. As the wheat passes through your digestive system, it gets slightly transformed, and traps air bubbles from the carbon dioxide you breathe out. One yeast alone can’t make much difference, but then comes your secret power: fission. As you eat, you gradually divide into two and become…two yeasts.

And then four.

And then eight.

Before you know it, your land of wheat is overrun with yeast. It collects more and more carbon dioxide and begins to rise!

Now, here’s a thought: what if there was something else inside the yeast? When the yeast multiplies, would that something inside get multiplied too

What, in fact, is leather?

You could start my saying “Imagine an animal…” but that takes us in the wrong direction. We need to approach the question in the same way we’d answer “What is a cake?” with “A composition of flour, butter, eggs, sugar and soda mixed together and baked till it’s cooked”.

In the case of live animals, the chief ‘ingredients’ are amino-acids, which link up together to form chains. These chains, in the correct configuration, are known as proteins. Every type of protein is made up of a certain specific sequence of amino-acids—or, to put it another way, different sequences of amino-acids combine to form different kinds of protein.

The animal body is more complicated than a cake, but it is still made up of specific ‘ingredients’, so to speak. Chief among these are proteins — large biomolecules that play various roles in the body. They’re the ones who do most of the work inside your cells. They help your tissues and organs function properly, and also let them retain their structure without collapsing. If your body were a cake, then proteins would clearly be the baking soda.

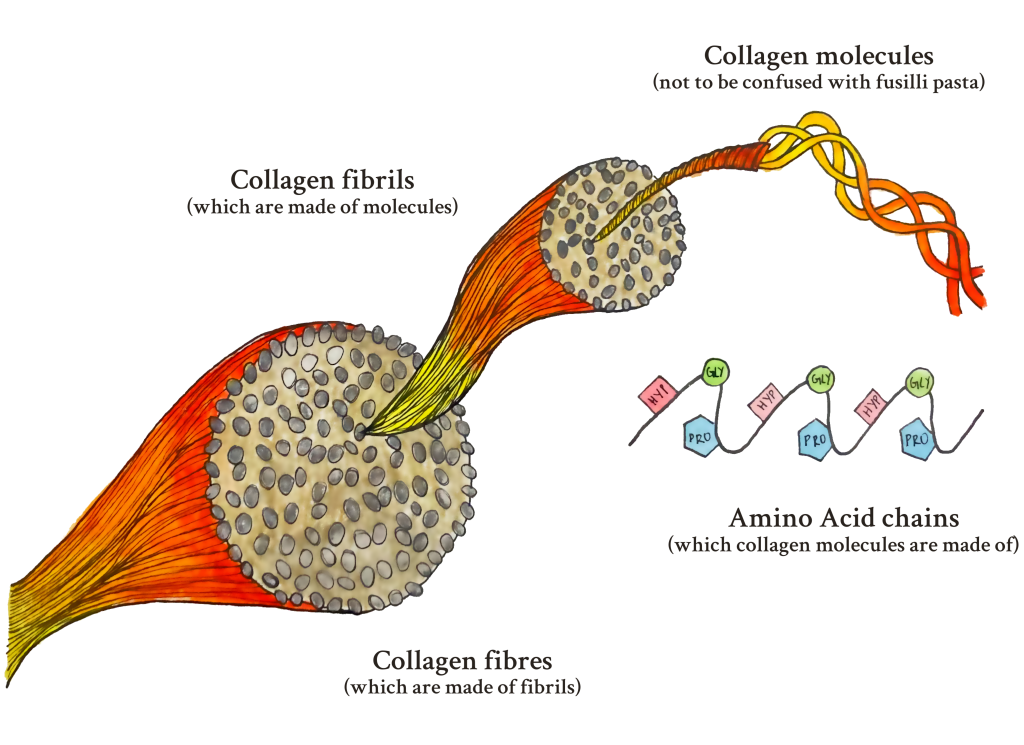

There are many kinds of protein in the animal body, but what we’re most interested in here is one called collagen. This is by far the most abundant protein in mammals — it accounts for about 25% to 35% of our proteins. It has a tight triple-helix structure (think three spirals spiralling round each other like a fusilli pasta), which makes it very strong.

That’s why collagen forms the organic part of bones and teeth, as well as in tendons and artery walls. When you get hurt and your skin gets cut, a scar quickly forms to cover it up: a scar made of collagen.

Take a look at the labels in the diagram above. There's a chain that constantly just goes: Hyp, Gly, Pro, Hyp, Gly, Pro. These labels represent different amino-acids, where Hyp, Gly, and Pro, are short for glycine, proline, and hydroxyproline respectively.

And that, my friend, is the molecular way of identifying skin—and leather.

Leather is known to have a pattern of (Gly-X-Y), where X and Y are often proline and hydroxyproline respectively. Three chains of these go together to form tropocollagen, which is the structural unit of collagen. These spirals form nano-fibrils called "collagen fibrils", which in turn combine to form collagen fibres.

Not surprisingly, collagen is what makes up skin as well. Imagine all those collagen molecules tangled together into a kind of mat, which covers all the flesh and veins inside your body: that's skin. Cows have skin too, but it’s thicker so we call it ‘leather’.

So now we know our secret ingredient: collagen. If we have that, we almost have leather. But we can’t just go out and buy a jar of collagen; we have to manufacture it somehow — and then, once done, we have to put those parts together properly.

This process is known as ‘biofabrication’, but I like to think of it as a set of Legos.

Now, in the world of biology, Lego has a special superpower: if you take a live colony of Lego blocks, it can grow new Lego blocks to expand the colony. Of course, our Lego is nothing but proteins! That's how people grow meat in labs, and it's one route to growing leather. We take some real, live animal skin, and dip that into a nutrient tank so it can continue to grow.

The problem is, this product isn't completely animal free: the starter skin still has to come from somewhere. What's more, the nutrient tank is attractive to more than just a skin colony, so we may get uninvited guests like other bacteria and yeasts trying to mooch it off—unless we're very careful to maintain sterile conditions, which will drive up the cost further.

Instead, what we're going to do is much like what the Lego company does: create a Lego factory to make our own Lego blocks—I beg your pardon, proteins—from scratch.

Imagine if you bought a set of Legos — say a Lego Harry Potter. Now, with the many different Lego pieces, you’ll be tempted to reassemble it into Batman, or into a spaceship. Although it’s intended form is Lego Harry Potter, it can be reassembled and made into a spaceship.

Similarly, in biofabrication, we are using the same Lego blocks but changing it into something else. In our case, the leather blocks are protein, and our spaceship is…leather!

Thousands of years before agriculture was a thing, people were already using yeast to raise bread. Ten thousand years ago, people started brewing alcohol in an organised fashion using honey and wild yeasts.

Today, researchers are going a step forward by using yeasts for something new: precision fermentation.

Precision fermentation is basically a more evolved form of traditional fermentation. With this technology, we’ll be able to hack into micro-organisms to produce complex organic molecules like proteins.

In our case, we’ll be engineering our yeast strains to produce a greater amount of hydroxylated protein and carbohydrates, which can then be used to form leather.

The first step is to take a plasmid—that is, a circular piece of DNA containing the instructions we want—and insert it into some yeast. In this case, we're inserting DNA that will help us produce proteins.

Precision fermentation is basically a more evolved form of traditional fermentation. With this technology, we’ll be able to hack into micro-organisms to produce our own proteins—and the way we do that is by sending them instructions through DNA.

So the first step is to take a plasmid—that is, a circular piece of DNA containing the protein-making instructions we want—and insert it into some yeast.

Gene insertion is a finicky business, and not all yeasts accept the plasmid properly, so we now need to kill off the ones that don't. Yeast selection, and cell selection in general, is done using something called an ‘auxotrophic selection marker’. Auxotrophy means the inability of an organism to produce an important thing, and that's exactly what these markers do: prevent the cell from synthesising something essential.

And now comes the trick: along with the new plasmid we're inserting, we include the ability to synthesise that same essential something. The result? The yeast which accepted the plasmid will continue life as usual, but the others, unable to produce all they need, will soon die.

Gene insertion is a finicky business, and not all yeasts accept the plasmid properly, so the next thing we need to do is kill off all the other yeast. This happens through a sort of reverse-poisoning: take away the power to produce some essential substance, and then, through the plasmid, give that ability back. The yeast with the plasmid will survive; the rest will die.

Once this ordeal is over, the surviving yeast are put into yeast heaven: a nutrient-rich solution in which they can live. And then, yeast does what yeast will do, which is to divide and multiply. The yeast’s body grows and begins to split. The yeast’s DNA duplicates itself too; half for one body and half for the other. And — here’s the key part — the extra genes that were injected get multiplied, divided, and passed on too. As fermentation continues, we have a growing colony of yeast, each individual having the special genes we inserted.

In this case, the special genes includes one called kgtP which is very good at making our original building-blocks: proteins.

Modern Meadow doesn’t aim to exactly replicate cow leather. Instead, it wants to make something that’s as good as leather, or maybe even better. It should be washable, waterproof, and, in short, have all the same features that leather does.

This is where all the other inserts come in.

You must understand that there’s a lot going on in there. The kgtP gene’s job is to create something known as an alpha-ketoglutarate transporter. This transporter brings in its namesake molecule, the alpha-ketoglutarate, which is the one that stimulates protein synthesis. The gene makes the transporter; the transporter brings in the molecule; the molecule is the one that actually causes more proteins to grow.

Then there's hydroxylation. Remember the triple-helix fusilli-pasta structure from earlier? If this structure is unstable it can easily fall apart, so we need stability. Hydroxylation is the process of adding a hydroxyl molecule to an organic substance. In our case, the hydroxyl is added to the amino-acid proline (of Hyp-Gly-Pro fame) to form hydroxproline (does the name sound familiar?). This is just one example of the detailed analysis and engineering that goes into deciding what to ferment!

Similarly, Modern Meadows would use a protein for hydroxylation — that is, adding hydroxyl molecules into our spirals to make them stronger.

There could be other inserts for stuff like “enabling an ascorbate synthesis pathway” or “overexpressing certain proteins”, but the upshot is that, with this new way to brew, researchers can add in anything the want to fine-tune the end results — just as you’d modify a cake recipe to make it your very own.

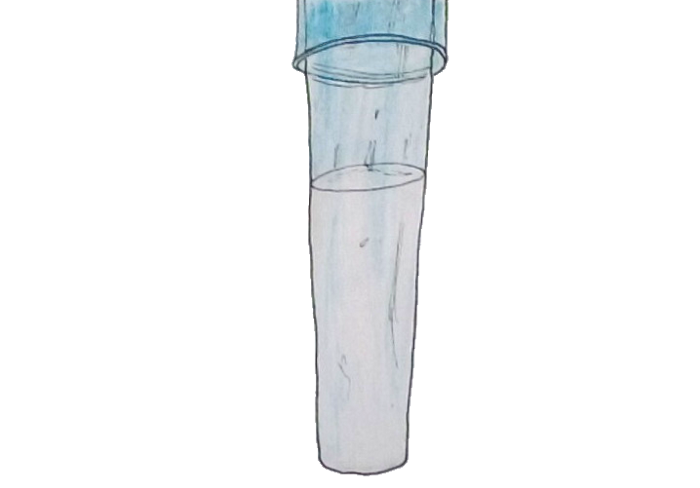

Now, if you’ve been following along with the story of alcohol, you’ll realise there’s a slight problem. By injecting the right ingredients, we will end up with collagen — the same material used to make skin. But if you use the same methods you use for alcohol, you’re bound to come up with something that’s a bit like alcohol. And sure enough, the collagen we end up with looks like this:

Instead of making cow skin, did we accidentally make cow milk?

Actually, the next process is to fibrillate the collagen. Fibrillation is the process of producing collagen fibrils, and this is usually done by increasing the pH or adjusting the salt concentration of the solution. This fibrillated collagen can be processed to mimic the properties of collagen fibrils produced by particular species.

Sometimes during fibrillation, the collagen gets a little naughty and forms a hydrogel (a cross-linked network of collagen). When this is formed, we can further stabilise it by introducing different molecules to it.

Actually, the next process is to fibrillate the collagen. Here, that means increasing the pH or the salt concentration to turn the liquid into a solid fibre. As it solidifies and dries out, the collagen proteins will end up forming the fine, interconnected mesh we were hoping for: a mesh so fine that even water can’t easily pass through.

We may also add other proteins during this process, depending on the functionality and aesthetics we desire. This flexibility allows us to tweak the end-product in ways that would be impossible with conventional leather. `

From here comes the post-processing: drying out the water, dyeing in the colour, dripping in the lubricant to let the fibres slide smoothly against one another, and, eventually, delivering it to the customer. But we all know how this works, because it works more or less the same way even for ordinary leather.

Here's a fun tidbit: Modern Meadow introduces colour to the materials when they're in liquid state, making the dyes chemically bind directly to the proteins. This helps eliminate dye run-off from material manufacturing: the colour's attached as fast as any colour can be!

Before we leave this, though, let’s take a step back and look closely at what we’ve made. On the surface, it looks like the leather of ten-thousand years ago, although the technology to create it has improved a thousandfold. Zooming in, you’ll find a scene more reminiscent of fabrics: fine fibres woven tightly together; more tightly than most handmade fabrics can manage. The collagen fibres are much messier and more haphazard — but that doesn’t matter, because the haphazardness is so small we won’t usually see it. The fact that it’s collagen reminds us that this is, at the end, simply a variant of the skin we always have on.

So what is it, exactly, that Modern Meadows has made and is going to make?

The future of leather, it turns out, is also the future of fabric.

Action items: This is the future—-and you can be part of it too! Check out Modern Meadows and ZOA materials to get educated and get involved. Oh, and don’t forget to sign up for my newsletter!

Meet Rania: If you want to jam out on this or just be friends (pretty please), catch me on my socials — Linkedin | Twitter | Instagram | Youtube. Oh, and while you are at it, stay on the loop with my crazy adventures by subscribing to my personal newsletter! Toodles :)